Site Content

The Fiber Recycling Process

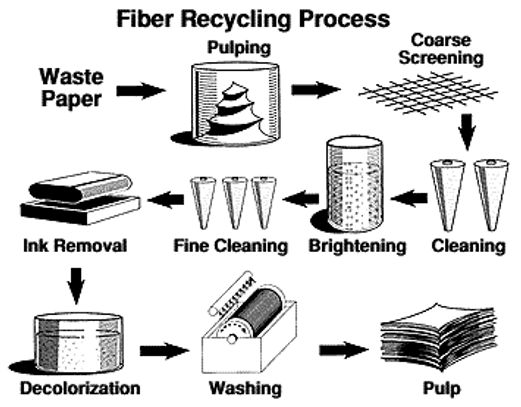

Simply put, fiber recycling is a specialized process in which office wastepaper is used to produce clean, recycled pulp that can be used to make recycled content paper and paperboards. At a Recycling Plant, located in Franklin, VA, more than 400 tons of mixed office waste, the equivalent of 80 million sheets of 8.5" x 11" paper, can be processed daily. From that, 300 tons of 100% post-consumer pulp is made for producing recycled content business and printing papers and bleached paperboards... all of which perform like non-recycled products.

Wastepaper from office, school and business recycling programs is collected by outside waste-management companies that sort the waste and then sell it in bales to the mill.

About 22,000 pounds of wastepaper goes into every batch of pulp this mill makes. The wastepaper is mixed with water and chemicals, and reduced to pulp slurry in a giant blender called a pulper.

Site Content

Following pulping, the pulp mix is diluted with water and passes through a system of centrifugal cleaning equipment and screens. This is done to remove large contaminants like wood, plastic, rocks, glass and paper clips, along with small contaminants like string, glue and other sticky materials.

The pulp is pressed to remove water and dissolved inks, and is then fed into a kneading machine. During kneading, the pulp fibers are rubbed against each other, further loosening the inks, while kneading chemicals are added to begin the brightening process. Brightening the pulp counters any yellowing affect sometimes seen in paper containing wood fibers like those used for newspaper. The fibers soak in chemicals for about three hours in a storage chest. The pulp that went into the brightening process gray and dirty in appearance comes out much whiter and cleaner.

The fibers are then sent through a fine screening process that removes any remaining glue particles and small contaminants.

The pulp goes through an ink removal process. Here the pulp is mixed with chemicals, called surfactants, that suds up like washing machine soap. Ink particles, dirt, glues and other very small contaminants adhere to the suds and float to the surface where they are skimmed away leaving the pulp even cleaner.

The pulp is then washed, pressed, kneaded and placed in the decolorization chest. A chemical is added to remove any colors that might tint the pulp.

The pulp is then washed again to remove any remaining ink particles, fillers or other contaminants.

The finished recycled pulp is then either sent on a mile-long conveyor to the mill for papermaking or it is formed into sheets of pulp, called "wet lap," for shipment and sale.

Paper Trading International, Inc.

9052 Valley Crest Ln, Germantown, Tennessee 38138, United States

Copyright © 2023 Paper Trading International, Inc. - All Rights Reserved.

pc0j0uih3mvk47fduimd8pn0or